IT’S GOOD TO HAVE A TREAT THAT’S HEALTHY

Ludmila Lapshina, Sales Support Technologist, LLC Rusagro-Saratov

Rusagro Holding holds one of the leading positions in the market of specialized fats and margarines. For many years the company’s specialists have been improving technological processes for processing vegetable oils and fats. The field of application of “Solpro” TM products covers practically all branches of food industry. The ice cream industry is no exception.

Currently, ingredients for ice cream production include milk and milk products; milk fat replacers (MFRs); sweet products; stabilizers and stabilizer-emulsifiers; food flavoring products and food additives; and functional foods. Ingredients used in the production of ice cream determine the classification, qualitative indicators (chemical composition, organoleptic properties, nutritional value) and technological functionality.

EQ is the most important ingredient used in milk-containing products. It determines the flavor, appearance and consistency as well as the stability of the final product. When selecting HFAs for each name of milk-containing products, it is necessary to take into account the correspondence between the requirements for the final product and the technological properties of fats (melting point, TTH content at different temperatures and fatty acid composition). Fat in ice cream affects the consistency and structure of the product, which affects not only its thermal and form stability, but also the organoleptic sensations when consumed. It also determines the processability of the mixture during ripening and freezing. In this regard, the requirements to the physical and chemical parameters of fats used in the production of ice cream are special.

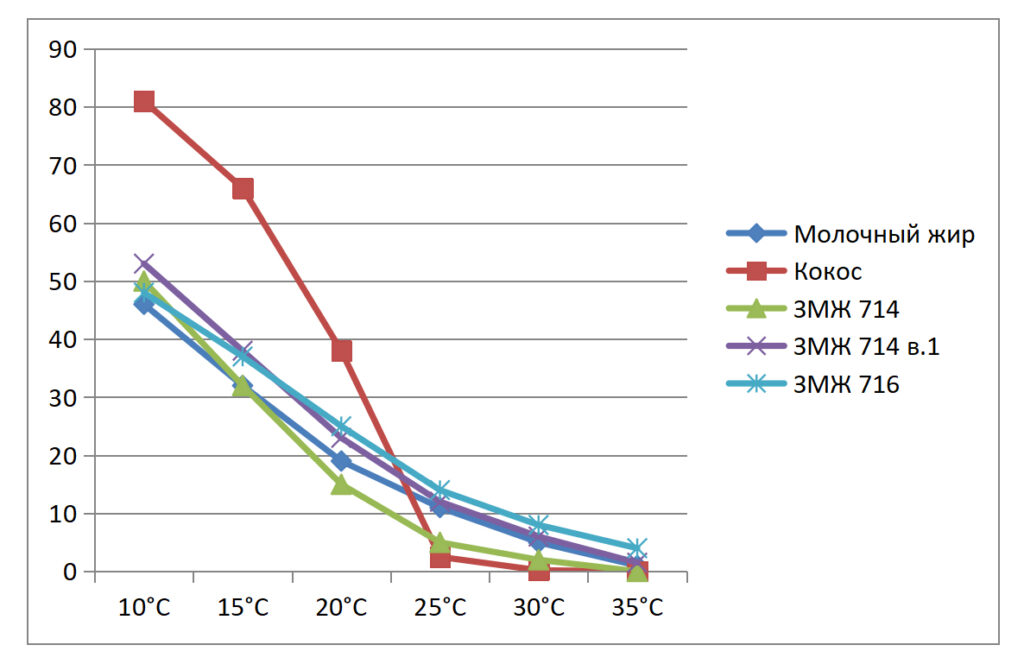

Requirements for physical and chemical parameters of fats for ice cream include their fatty acid composition, content of solid triglycerides at temperatures of 10°C, 20°C, 30°C, 35°C, melting point.

Thus, the content of solid fat at 10°C is not less than 45% necessary to ensure the effectiveness of ripening and freezing processes that determine the consistency and structure of ice cream. Minimal solid triglyceride content at 35°C eliminates unpleasant flavors such as “saltiness” or “fat envelopment”. The melting point of the fat determines the melting characteristics of the ice cream in the mouth and must also be taken into account when transporting the fat.

A notable step towards improving the quality of ice cream with vegetable fat in our country was the requirement of TR CU 033/2013 to use only milk fat replacers as vegetable fats in the production of ice cream, which is reflected in the name of the product – “ice cream with milk fat replacer”. This regulation establishes requirements for physical and chemical parameters of ice cream with EQM.

The specified requirements for HFG of TR CU 024/2011 and TR CU 033/2013 in terms of replacing no more than 50% of milk fat with HFG allow to make ice cream with a higher content of unsaturated fatty acids not only in comparison with coconut oil, but also with milk fat. This increases the nutritional value of the product as a whole, but requires a more careful approach to the selection of EQ for ice cream.

Firstly, the applied HFCs should not disturb the process of milk fat crystallization in the formation of the product structure, and secondly, the presence of triglycerides in the composition of HFCs with different crystallization temperatures contributes, as in the case of milk fat application, to the formation of the organoleptic sensation of “fullness of taste” when consuming the product.

Currently existing methods of vegetable fat modification allow to produce milk fat substitutes, which have characteristics (physicochemical and structural-rheological) close to milk fat.

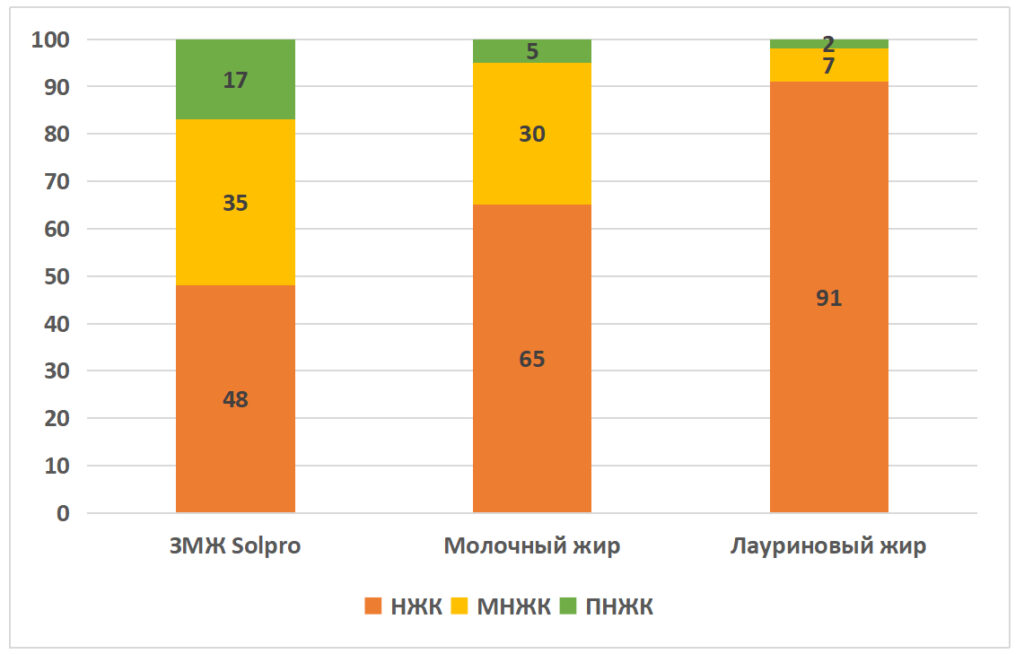

A distinctive feature of milk fat replacers for ice cream is a balanced fatty acid composition, unlike coconut oil, which has a saturated fat content of more than 90%. Comparison of the solid triglyceride content of milk fat replacers and coconut oil is not correct. The melting curves of EQ are close to the melting curve of milk fat.

Comparative analysis of saturated, monounsaturated and polyunsaturated fatty acid content

*

SFAs are saturated fatty acids;

Monounsaturated fatty acids are monounsaturated fatty acids;

PUFAs are polyunsaturated fatty acids.

Melting curves of “Solpro” milk fat and coconut oil SFAs

Rusagro-Saratov produces milk fat substitutes for ice cream, which provide the product based on them with high organoleptic characteristics and good form stability.

The trend of replacing milk fat with vegetable fat, which has been developing in Russia for the last 15 years and abroad for several decades, is justified by some manufacturers by the desire to reduce the cholesterol content in the product, and by others – by economic aspects of production.

Full or partial replacement of milk fat with vegetable fats allows not only to reduce costs and increase productivity, but also makes it possible to expand the range of ice cream, to develop products for therapeutic and dietary purposes with less or no cholesterol, to balance the content of saturated and polyunsaturated fatty acids, etc.

As a result of experimental studies, it was found that the percentage of replacement of milk fat with vegetable oils depends on the mass fraction of fat in the mixture. In the production of dairy ice cream (with a mass fraction of fat not exceeding 12 percent) it is possible to completely replace milk fat with its substitutes.

Benefits of using milk fat replacers:

– allows replacing milk fat in formulations, which reduces the cost of production and increases the profitability of production;

– makes it possible to maintain production volumes in the period of raw milk deficit (which reaches 30%, approximately the same amount is the deficit of animal oils);

– provides a balanced fatty acid composition with an optimal content of polyunsaturated fatty acids, which are essential components of a healthy diet; the fatty acid composition of milk fat is the same regardless of seasonality (the fatty acid composition of milk fat depends on many factors: time of year, breed of cow, method of oil production, etc.);

– allows you to get a product with reduced or no cholesterol;

– extends the shelf life of ice cream;

– gives the ice cream the appropriate texture and consistency;

– determines pure taste and smell of ice cream, good flavor and aroma release of fillings.

By its composition, ice cream with milk fat replacer is a complete dairy product. Thus, the use of EFA in the production of ice cream simultaneously with milk fat can significantly improve the quality parameters of the finished product. In the case of technologically justified selection of EFAs, ice cream with their use does not noticeably differ from the traditional product at the same mass fraction of fat. In this regard, special attention should be paid to the selection of EQ for ice cream.