Rusagro Maslo is a significant part of Rusagro Group, handling its oil&fats business and occupying a leading position at the Russian oil&fats market. Industry leadership became possible thanks to the wealth of experience, expertise and professional quality of the company staff. Our unique knowledge is the foundation of tomorrow’s successful development strategy. It wouldn’t be an overstatement to say they now help shape the Russian oil&fats industry.

SOLPRO, the first-ever Russian brand of margarines and fats intended for bakery, confectionery and dairy industry, established 16 years ago to keep and develop traditions of a 80-year-old production facility.

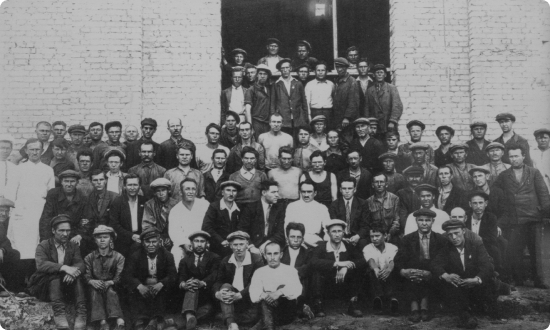

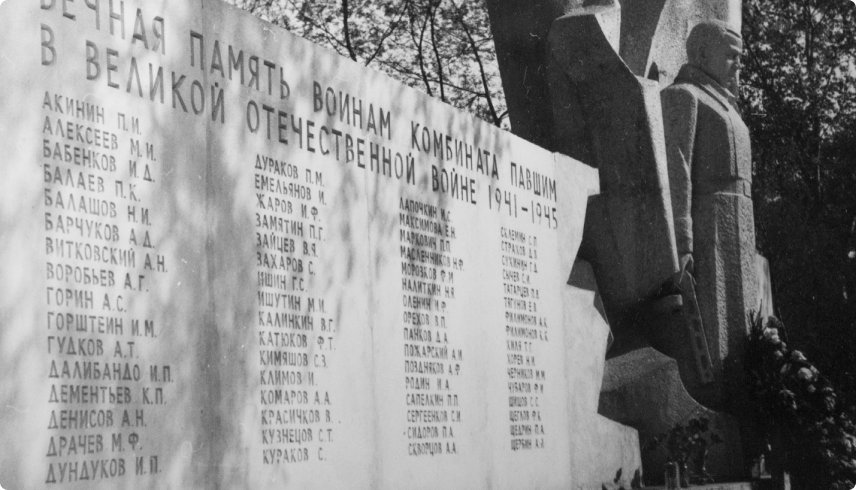

There’s a great history of victories and overcoming challenges behind the saying, “We know everything about fats and margarines”. It starts in 1935. That year, the first hydrogenation plant in the USSR was launched (renamed to Moscow Fat Integrated Works in 1965). It manufactured food-grade shortening, hydrogenated solid fat supplied to margarine factories.

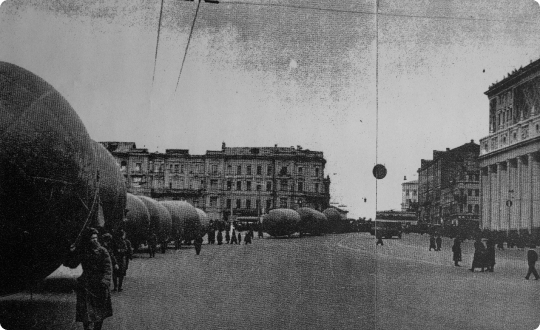

By 1940, the gas workshop was commissioned, and the production capacity went up three times. Additionally, the works started producing hydrogenated fat to be processed at food concentrate, confectionery and bakery factories. A shop producing emulsifier for margarine industry, the very first in the country, was also put into operation.

The decision to build a fat integrated works in Saratov was made the next year after the war ended. The construction lasted seven years; workforce shortages made oil refining and margarine production professionals change jobs and join the construction.

In 1953, the first stage of construction was completed and launched into operation: hydrogenation and gas facilities, boiler and oil drain stations.

Setting up production, preparing chemicals in the laboratory, connecting equipment: all of this had to be done from scratch by people without any relevant experience, from managers and engineers to equipment operators. Engineers and technicians studied, passed exams and worked together. Since then, out tradition is our ever-expanding expertise.

Researchers from Fats Institute and Main Margarine Department helped with their advice and comments. Finally, in October 1952, they successfully overcame the challenge of getting quality hydrogen out of natural gas! Month from month, the staff was getting stronger and more experienced, branching out into the more sophisticated areas of production. That’s how our approach to our job developed.

It’s our tradition to seek innovation, strive toward greater production quality and mobilize to solve new issues. Our modernization activity is a testament to that. Over 350 modernization projects have been implemented in the Soviet times after the plant launch.

Saratov factory today is Russia’s largest producer of margarines and fats for food industry and the main site implementing corporate innovation projects.

In 2007, we launched the only fat enzyme interesterification unit in Russia (the green technologies).

In 2011-2013, the plant got a process overhaul, with high efficiency multi-purpose margarine and fat production line made by Gerstenberg Schroeder (Germany-Denmark) being installed and the launch of fat and oil bleaching and deodorization facility.

The plant is in line with the highest quality standards; its workshops are equipped with cutting-edge machinery, laboratories, information and applied technology center: everything to supply the food industry with the highest quality product. GOST ISO 9001–2011 international quality management standard and FSSC 22000 food product safety management system are in operation. In 2016, we got a McDonald’s supplier license and started supplying our products to that global fast food chain.

In 2018, after the new TR CU regulation was adopted, limiting the trans isomers content in foods, the plant updated its recipes and process technologies. In 2020, we launched the CLEAN&FREE for palm oil free products. The properties of that line are the same as in ordinary margarines. They are produced through chemical interesterification, guaranteeing the desired consumer qualities and the required trans isomer content.

Saratov factory keeps developing. In 2021, a cutting edge PET bottle filling line was installed. The modern machinery will help raise the output of highly demanded products: frying mixes and high oleic oil (HOO).